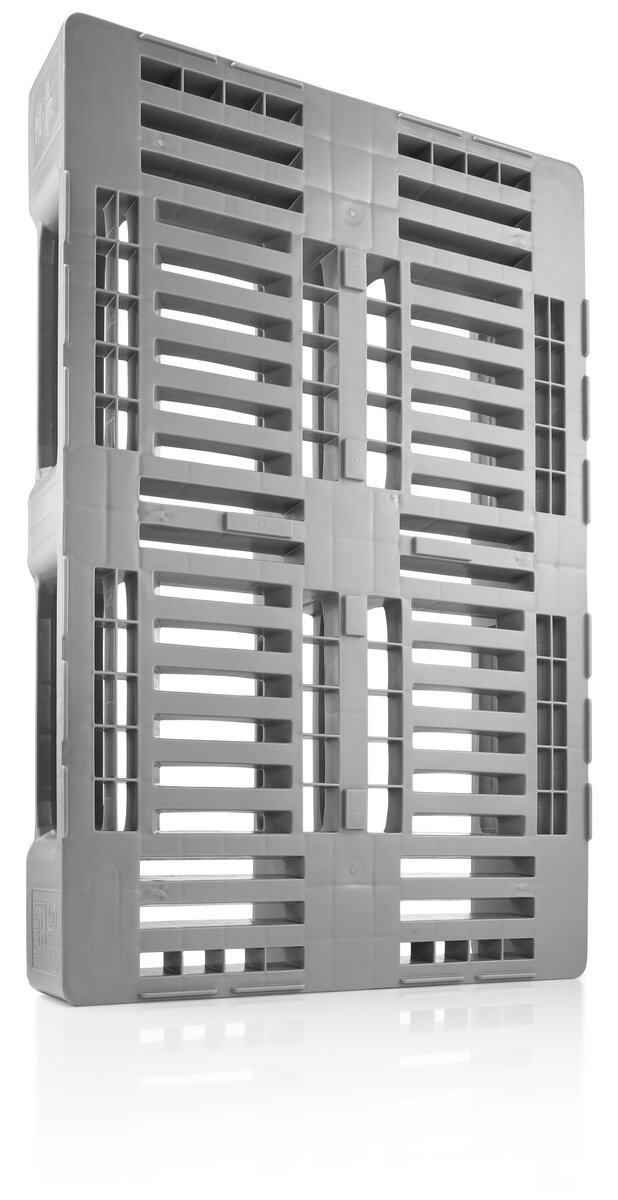

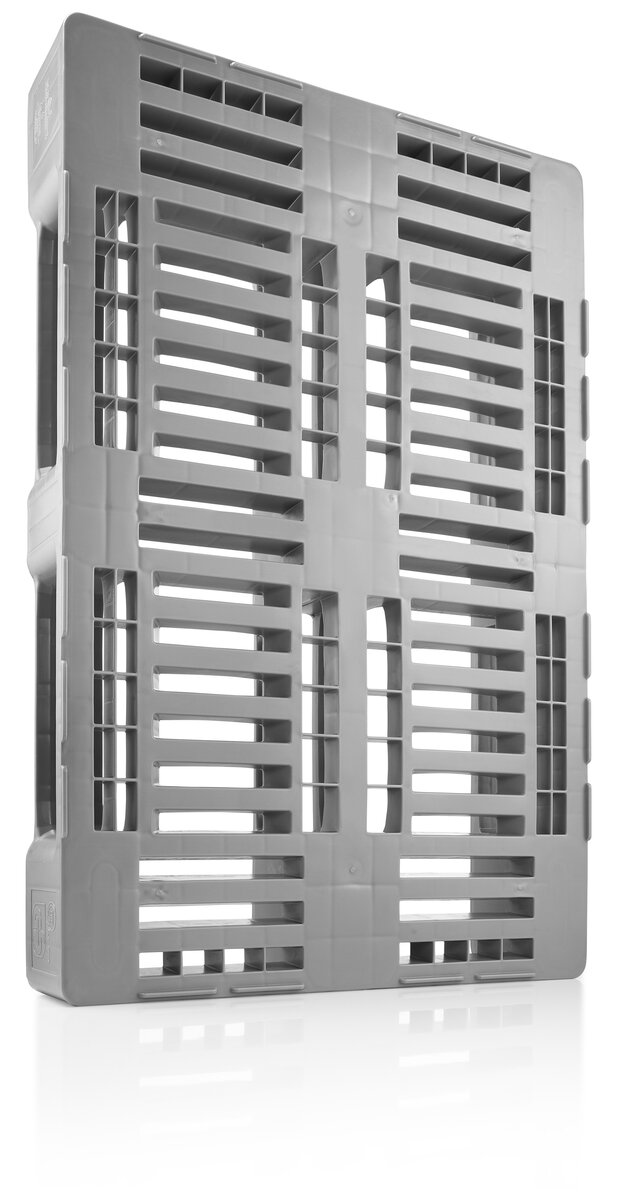

Non-Stop

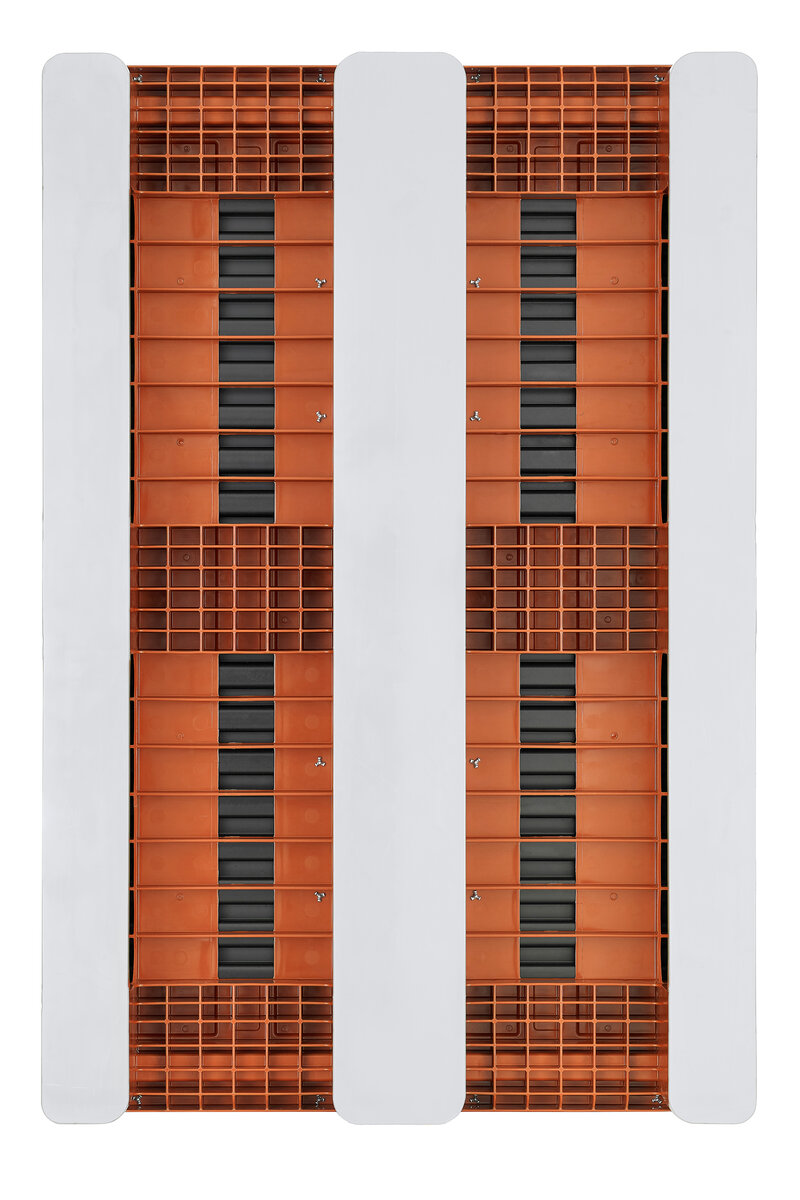

The Non-Stop pallet was specifically designed for use in the automated printing industry and guarantees uninterrupted logistics processes for delivery and removal of paper stacks in all standard formats. The optimal arrangement of the bridges on the thermoformed top deck of the print shop pallet ensures a fault-free removal of stacks via the Non-Stop stacker (computing system) of the printing machine.

Characteristics:

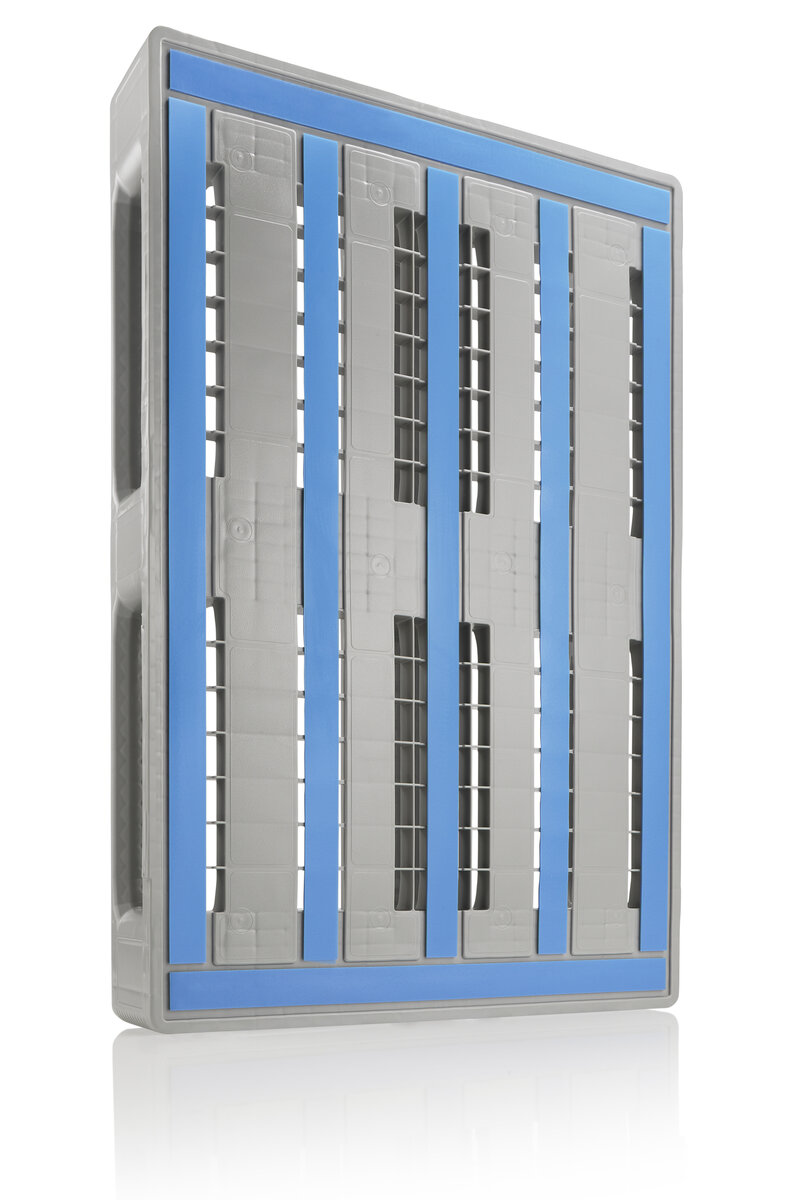

- Euro pallet with screw-fitted thermoformed top layer

- Specially developed for use with Heidelberg printing machines

- Interruption-free processes in the production sequence

- Welded runners for smooth running on automated systems

-

Technical information *1

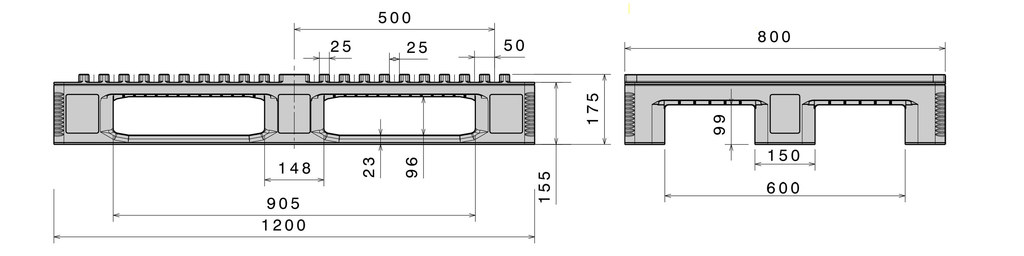

Internal Dimensions (mm) 1200 x 800 x 175 Temperature stability -30 °C to +40 °C, briefly up to +90 °C Art. no.Weight (kg)Load Capacity (kg) Static *3Load capacity (kg) Dynamic *3Load Capacity (kg) In Racking System *3ColourRunnersESDReinforcement profilesCentral box retainersRim (mm)Full-surface Palgrip® anti-slip top deckPalgrip® anti-slip strips on the top deckRetrofittable antislip plugsPalgrip® anti-slip runnersPalgrip® anti-slip pads on the top deck83241725 20 kg 7,500 kg 1,000 kg red brown / black 3, welded *1:

All technical data include characteristic features, which have been tested under specially defined conditions. Varying data may result from different conditions of usage such as loading method, prevailing temperature and length of storage time. All data and specified information are subject to change without notice. Our service team is pleased to be at your disposal to check the special requirements of your individual application.

*2:

Our service team is pleased to be at your disposal if you require exact information about material compositions.

*3:

Static load: resistance to pressure on a flat ground surface and an evenly distributed load at a room temperature of approx. 20 °C.

Dynamic load: on a forklift with an evenly distributed load at a room temperature of approx. 20 °C.

In racking system: evenly distributed load (sacks) along the longitudinal sides. Resting on two supports for over 100 h at a room temperature of approx. 20°C.

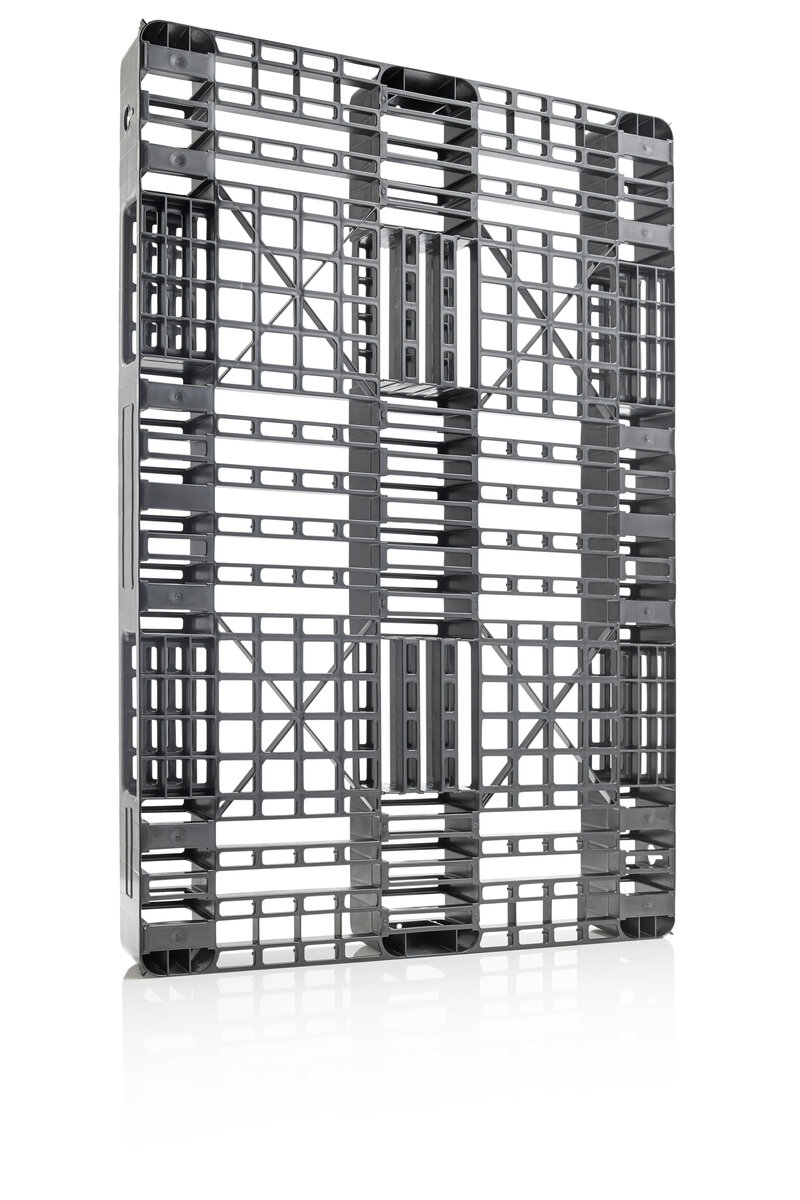

- Technical drawings

-

Loading quantities (Pcs / Approximate amount)

Container Container 20': 170 Pcs.

Container 40': 330 Pcs.

Container 40' High Cube: 330 Pcs.

Conventional trailer 45’ high cube container: 0 Pcs.Truck MEGA Trailer: 578 Pcs.

Jumbo: 612 Pcs. -

Labeling options

Customised printing and numbering available on request depending on quantity. Position upon consultation.

-

Technical drawings

Administration: Brocker Straße 1

Logistics, delivery, pick-up: Alte Ziegelei 2

33442 Herzebrock-Clarholz

Germany