In 1967 Craemer revolutionised the world market with the very first one-piece injection moulded plastic pallet. Today, with its injection-moulded polyethylene (PE) one-piece load carriers, the Craemer Group is one of the world's leading manufacturers of logistics solutions. The family-owned company is now launching another innovation – the E3-5 pallet. Even sturdier and with an even higher load-bearing capacity than their reliable all-round D3-5 pallet, the Craemer Group’s E3-5 is an all-rounder in the heavy-duty category – in high racking systems and in the field of automated conveyor technology.

Functional all-purpose pallet

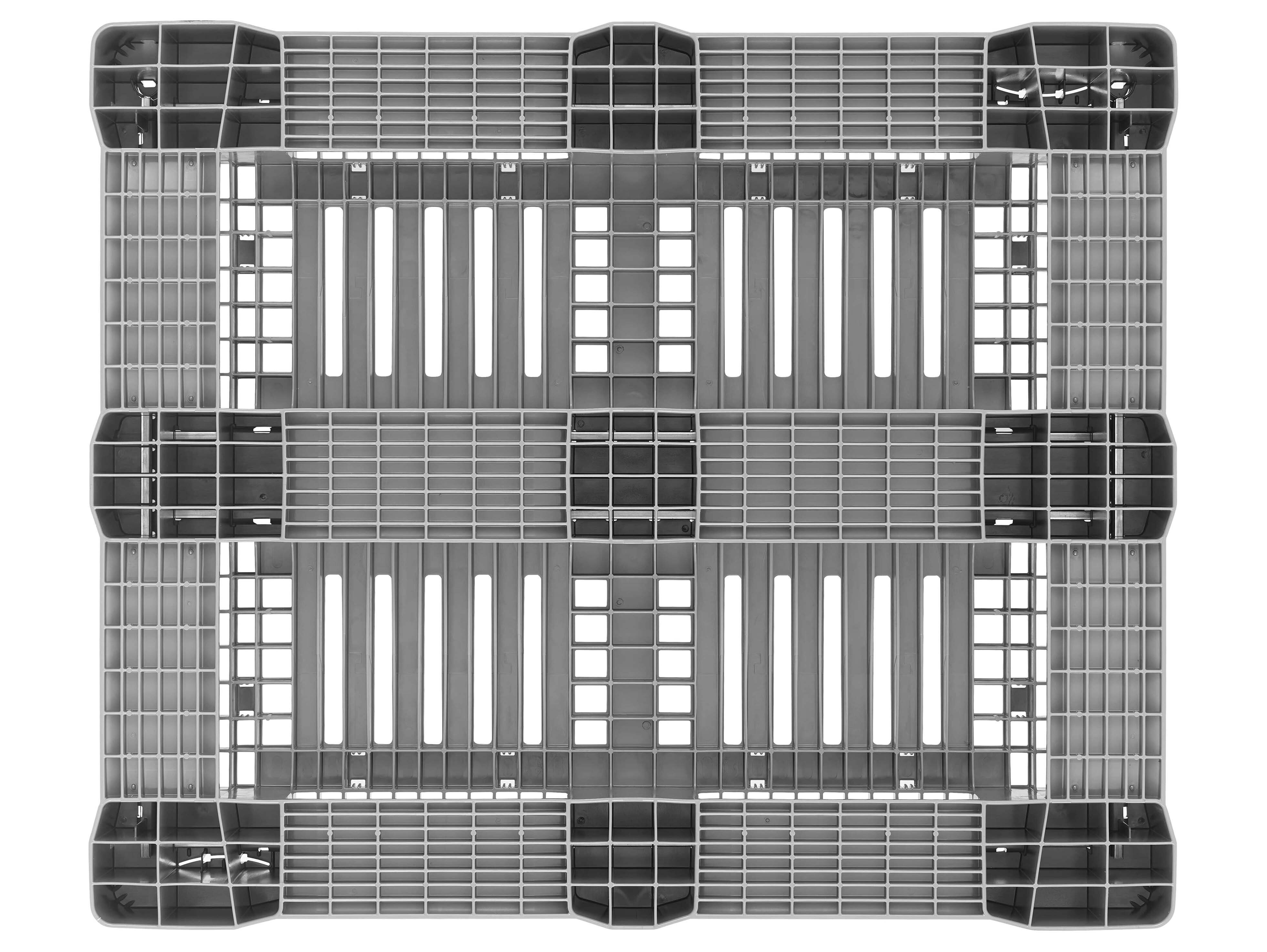

The new E3-5 has been designed as a 4-way all-purpose pallet in industrial dimensions (1200 x 1000 x 160 millimetres), with a tare weight of 24.5 kilograms. Including its five runners, the pallet is injection-moulded in one shot from high quality PE and 100 % recyclable. This versatile plastic pallet is also available as a three-runner version (E3).

Another special feature of the newcomer: The E3-5 is a heavy-duty pallet with a purist, functional design. The Craemer design team has deliberately dispensed with additional extras such as Palgrip® anti-slip strips on the upper deck or welded (anti-slip) runners, as these are not necessary for certain applications. On the other hand, the down-to-earth E3-5 pallet has strong features: Thanks to its thick walls and extremely robust design, it is very stable and reliable, shock-resistant and has a high load-bearing capacity.

High bending stiffness thanks to steel profiles

Its strength lies in its reinforcement profiles: Thanks to six metal profiles (four lengthwise and two crosswise), the E3-5 pallet has a high load-bearing capacity of 1400 kilograms in high rack (just like the CR3). Thanks to the two crosswise profiles, it is also extremely stable and robust along the short sides. The steel profiles visible on the upper deck, which are not fully enclosed, ensure a very high level of bending stiffness.

The heavily ribbed design of the runners also ensures extremely high robustness, resistance and therefore a long service life. This is further enhanced by the straight centre runners, which have neither recesses nor notches: They provide a stronger connection to the pallet body and protect the runners from breaking and cracking when under stress. This means that from the outset, the design avoids local stress peaks caused by notches that would reduce the strength of the body (notch effect).

Load safety guaranteed

To ensure that loads are optimally secured, the plastic pallet has a 5 mm outer rim as standard. Optionally, it is also available with a 7 mm or 22 mm rim. The pallet's slight oversize of a maximum of ten millimetres prevents damage to the load, e. g. cardboard boxes, as they do not rest on the rim. In addition, the E3-5 pallet has corners lugs on all four feet, i.e. non-slip retaining ribs for anchoring shrink wrap film.

Chamfered edges on both sides of all runners ensure optimum handling with forklift trucks. The E3-5 and E3 pallets can be fitted with twelve Palgrip® anti-slip clips to prevent slipping from the forks during forklift transport. These are clipped into the entry openings in the lower deck.

Features and options

Transponder pockets on each right foot on the long side of the new pallet allow retrofitting with an RFID tag for efficient tracking. On request, the E3-5 pallet can be fitted with recessed fields for barcode labels. Depending on the ordered quantity, printing options such as hot stamping of lettering, logos or numbering on the outer feet of the long side are also possible. Like all Craemer plastic load carriers, the new E3-5 pallet features a very high temperature resistance: It can withstand fluctuations from -30 °C to +40 °C and even up to +90 °C for short periods.

Versatile applications

As a universal pallet for heavy loads, the E3-5 is designed for a wide range of applications and can be used in the logistics processes of many sectors and industries. Thanks to its robustness and versatility, this new all-rounder for heavy-duty applications will also prove ideal for pooling. In short: the innovation made by Craemer is suitable for a wide range of applications – from high racks to automated processes.

With a load-bearing capacity of up to 1400 kilograms, it offers maximum dimensional stability, especially in high racks. This makes the E3-5 pallet suitable for all types of packaging (crates, boxes, containers, etc.) in the beverage industry as well as in tyre logistics. And in the food industry, it can also be used as a versatile pallet for pre-packed food. In areas where (intra)logistics can do without extensive anti-slip elements, the E3-5 pallet is the perfect alternative with an ideal price/performance ratio.

Administration: Brocker Straße 1

Logistics, delivery, pick-up: Alte Ziegelei 2

33442 Herzebrock-Clarholz

Germany