The Craemer plastics plant in Oelde (Germany), which opened in 2023, houses five injection moulding machines with clamping forces ranging from 3,200 to 5,500 tonnes. It is also equipped with several welding units and a range of extruders. Founded in 1912, the Craemer Group has been active in plastics processing since 1958. At the Oelde plant, used plastic products are transformed back into high-quality raw materials. Craemer’s recyclate, branded Zero Virgin, consists of 100% recovered and refined polyethylene. Thanks to the decades of expertise of Craemer specialists, it is of the highest quality.“The quality of our compound is comparable to that of virgin material,” confirms Ralf-Peter Finke, Technical Manager Plastics and Authorised Signatory. “In the field of large waste containers, it even surpasses it.”

Part of the circular economy

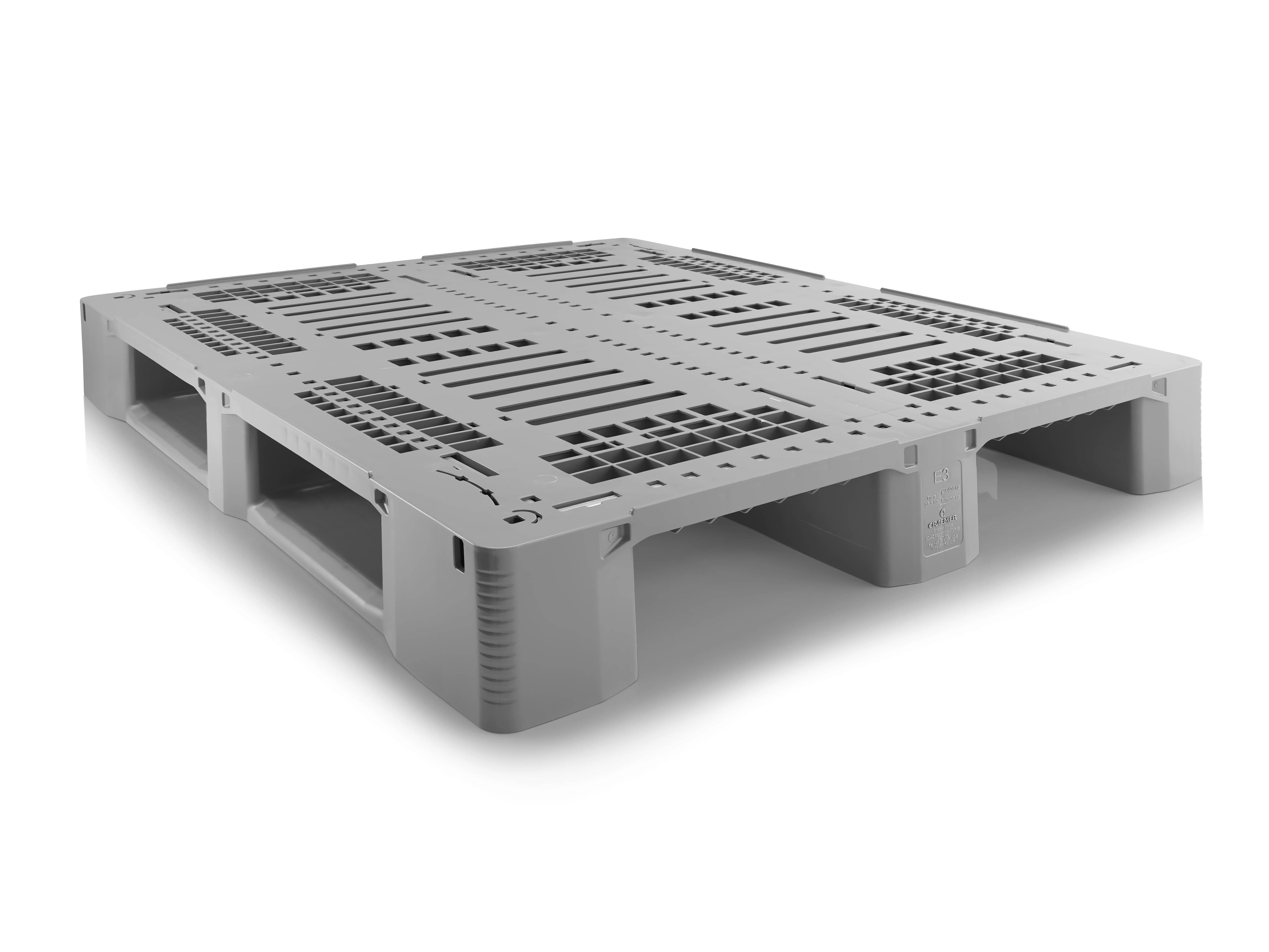

To help protect the environment, Craemer also manufactures its latest pallet development using its in-house recyclate. The plastics specialist guarantees that the E3-5 Zero Virgin has exactly the same properties as the version made from virgin material. Extremely robust, stable, impact-resistant and reliable, both versions of the E3-5 can carry loads of up to 1,400 kilograms in high-bay racking, are highly durable and fully recyclable. The Zero Virgin model also offers a significant sustainability advantage – provided that users return the load carriers to Craemer at the end of their life cycle. That way, both versions can continue to be an integral part of the circular economy.

Production with renewable energy

Further sustainability and environmental measures at the Craemer Group: at the Oelde plant, the injection moulding machines, and energy-intensive extruders will soon run on the company’s own renewable energy. By the end of the year, the company’s wind turbine will supply all the electricity. Since the end of May 2025, a photovoltaic system on the roof has already been generating energy, and another will be installed in the open area below the wind turbine.

To ensure a consistent supply of Zero Virgin material even during months with little wind or sunlight, Craemer has already expanded its granulate storage capacity by installing eight additional aluminium silos. Two of these are loading silos, designed for direct lorry filling and straightforward onward transport of the material to the production sites – whether Craemer’s own plants or those of granulate customers. The Craemer plant in Oelde now has a total of 20 silos with an overall storage capacity of around 4,000 tonnes.

Wind turbine currently under construction

In March 2025, a groundbreaking ceremony marked the start of construction of the company’s own wind turbine, just a few metres from the production hall at the Oelde site. With a hub height of 164 metres and a total height of 250 metres, the planned wind turbine will have a rated output of 6.8 megawatts and is designed to generate 16.5 million kilowatt-hours (kWh) of electricity a year – equivalent to the annual consumption of 5,000 households. “Our injection moulding plant in Oelde consumes roughly the same amount of energy as 3,000 households,” explains Ralf Westermann, Head of Facility Design and Procurement at Craemer. “We can feed surplus wind and solar power into the public grid or use it at our plastics and metal plant in Herzebrock-Clarholz, just a few kilometres away.”

Administration: Brocker Straße 1

Logistics, delivery, pick-up: Alte Ziegelei 2

33442 Herzebrock-Clarholz

Germany