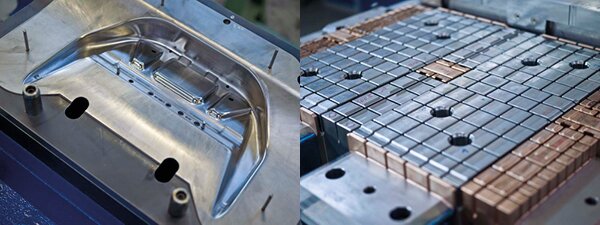

Tool for car seat-pan (l.) and mould for pallet (r.)

Craemer’s tool making sector manufactures tools for metal forming and moulds for plastics processing: with maximum expertise and on stateof- the-art machinery.

Maximum precision guaranteed

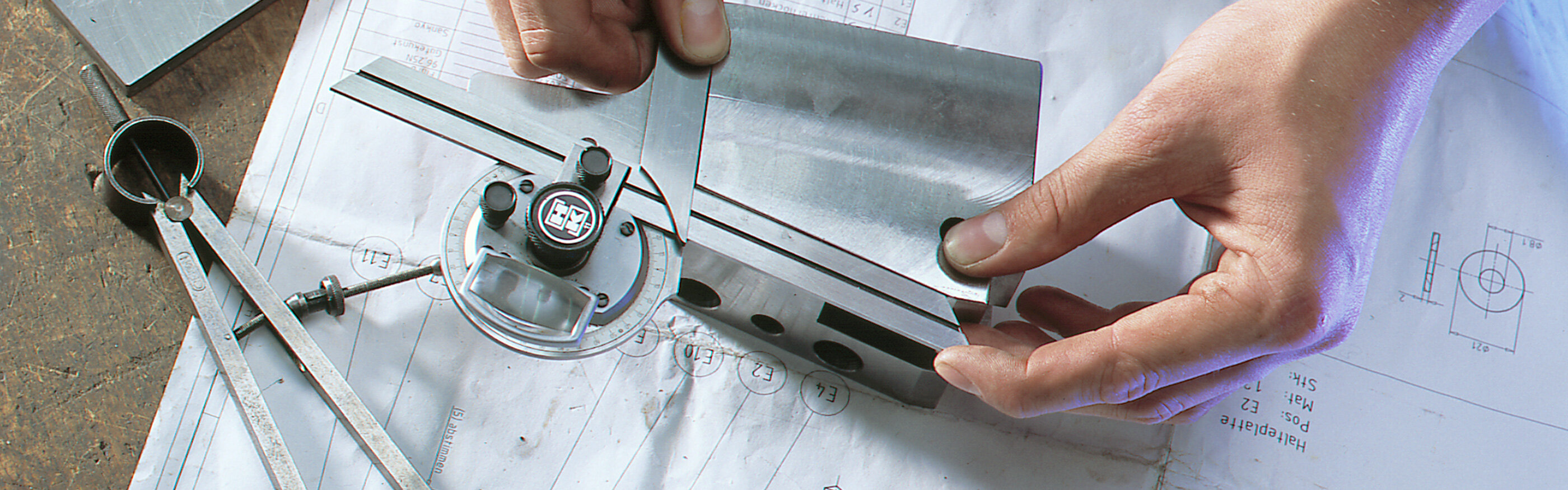

Shortly after Craemer was founded, the in-house tool making sector came into being and to this day it represents a significant advantage for the group. It has since constituted the interface between product development and manufacture. Up to the present day it has the function of an in-house service provider for the business activities of metal forming and plastics processing. The created tools and moulds are of the highest standards thanks to a clear priority on quality and precision. The tool making specialists’ competence and experience are essential: they come into play right from the beginning and guarantee the exact realisation of the construction specifications.

Quality and precision are top priority

Tool mechanics in the metal field make stamping and forming tools for prototypes as well as for mass production (transfer and progressive die). These tools are then used in the manufacture of automotive modules or metal components for large household and heating appliances. The moulds and installations for Craemer plastic products, such as storage and transport containers, plastic pallets or waste bins, are also developed and manufactured in-house.

Modern technology for complex tasks

The complexity of demands is increasing, whether it is for metal forming tools or moulds for plastics processing. At Craemer, a state-of-the-art machine park (e.g. the newest CNC controlled lathes, milling and erosion machines) is coupled with many decades of experience and precision-skills in the in-house tool making sector. This combination results in a (serial) production with constant low tolerance levels.

Administration: Brocker Straße 1

Logistics, delivery, pick-up: Alte Ziegelei 2

33442 Herzebrock-Clarholz

Germany