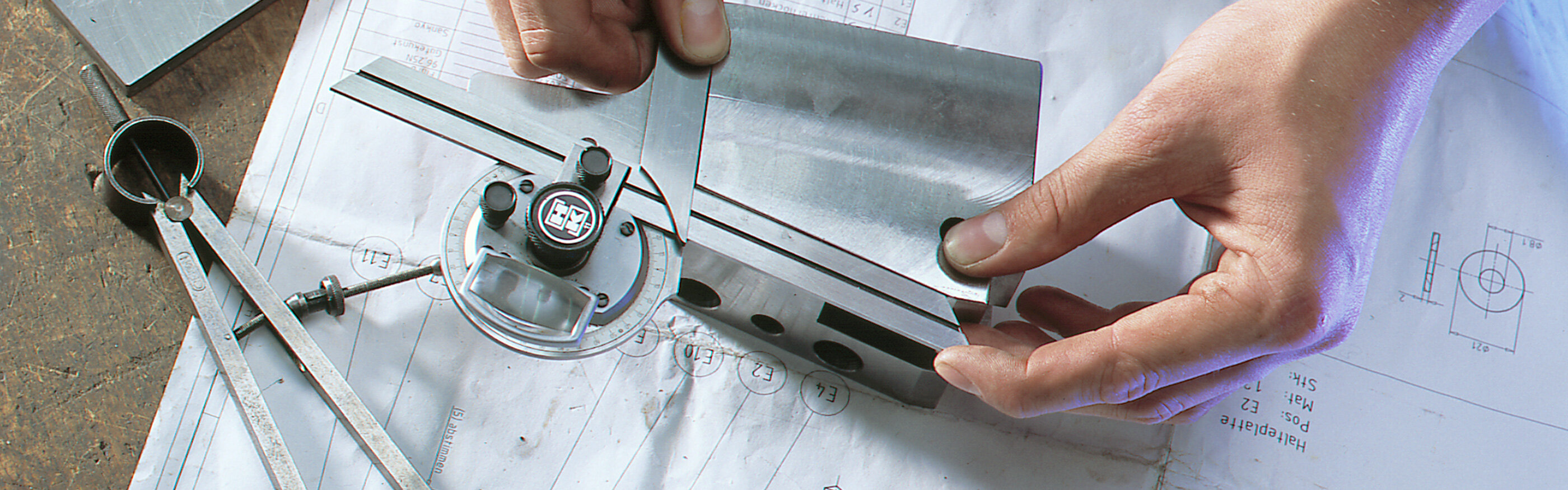

The construction department provides the design specifications for tool making: in close co-operation with skilled personnel from other departments, with well-founded know-how and at modern CAD /CAM work stations.

Basis for sustainable products

In close co-operation with the development department and the in-house tool making, tools are constructed at the company headquarters for the manufacture of metal and plastic products to meet the strictest requirements. The skilled employees in the construction department have ideal qualifications, having gained experience and well-founded know-how over several decades. During tool construction they take into account customer wishes and demands, product requirements, feasibility and producibility, and all this in close co-operation with Craemer’s quality assurance.

Use of modern technologies

Tool construction is carried out at modern CAD-/CAM work stations, for example with CATIA. Where necessary, drawing simulations on the basis of auto-form-systems offer the possibility to demonstrate the forming process at the computer prior to production. Feasibility studies or tests on stability and time-simulation of mould filling safeguard the ensuing tool making and production processes. The construction department provides the groundwork for the tool concepts, for the creation of the first samples/prototypes or for serial production.

Innovation is the future ability

Whether it is a question of making tools for sophisticated metal parts in close collaboration with the customer, or producing injection moulds for their own plastics programme, Craemer construction is always accurate and precise, innovative and sustainable with a view to the future.

Craemer House

Hortonwood 1

Telford, Shropshire TF1 7GN

United Kingdom

Free-phone number for your inquiry:

Wheelie Bins: 0800 032 4289

Plastic Pallets: 0800 032 4291

Fish Boxes & Containers: 0800 032 4292