HB3

The HB3 pallet box is the first and only completely closed pallet box on the market with welded runners. The box consists of two one-piece injection-moulded elements: the box body as the top part and the pallet with three welded runners as the bottom part. The box is extremely rigid thanks to the welding of top and bottom part. The bending stiffness can be increased with three metal profiles.

Construction and design of the box body ensure optimum hygiene. The smooth inner walls and the welded runners allow easy emptying, cleaning and drying. The almost invisible contour-milled welding seam, the clean and clear lines, the minimal ribbing and the rounded shape also contribute to this. The design of the hygiene box has neither any cavities nor ribs and provides reliable protection against contamination or water ingress. The double-walled design of the side walls above the entry openings provides increased impact protection against forklift tines, while the reduced entry height ensures smooth workflows in automated high-rack warehouses. Thanks to the robust, welded runners with high dimensional stability, the hygiene pallet box runs maintenance- and trouble-free on all conventional conveyor systems. The circumferential stacking step in the top and bottom rim also make the HB3 compatible with a wide range of other pallet boxes.

Characteristics:

- Composed of one-piece injection-moulded top and bottom part with 3 welded runners

- Walls closed

- Strong runner connection

- Double-walled side walls above the entry openings for increased impact protection against forklift tines

- Euro stacking system for compatibility with a variety of other pallet boxes

- Smooth interior walls for easy emptying and cleaning

- One closed drain port with integrated thread and drilling mark, each on one long side (2-inch) and on one short side (1-inch)

- Runs maintenance- and trouble-free on all conventional conveyor systems and is also suitable for automated high rack warehouses.

- Temperature resistant from -30 to +40 degrees Celsius, briefly up to +90 degrees, resistant to most chemicals and cleaning agents.

- Strippled area for temporary adhesive labels

- The container is based on DIN EN 13626 and DIN EN ISO 12048

Options:

- One closed drain port with integrated thread and drilling mark, each on one long side (2-inch) and on one short side (1-inch)

- Reinforcement profiles

- RFID Transponder

- Lid

- Palgrip® anti-slip runners

- Individual printing

- Different coloured upper part possible / lower part light grey

-

Technical information *1

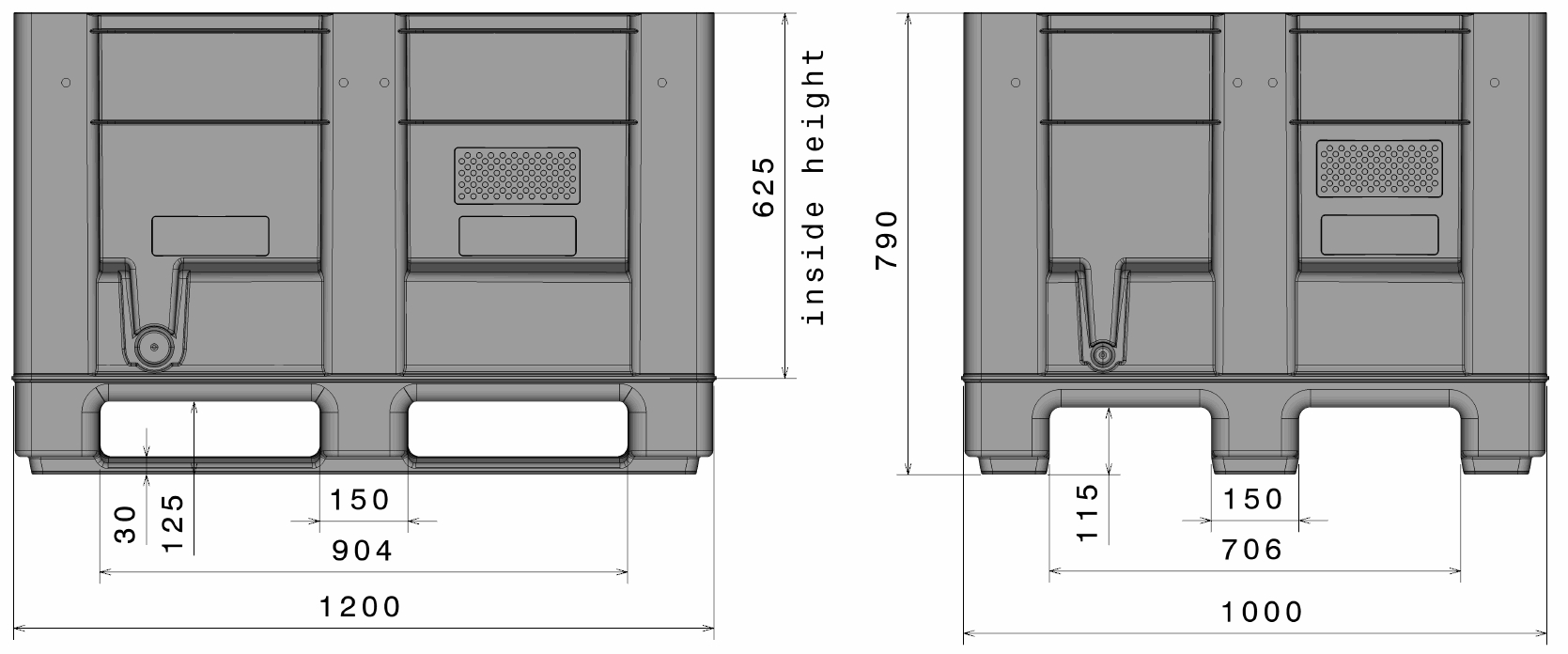

Internal Dimensions (mm) 1200 x 1000 x 790 Temperature stability -30 °C to +40 °C, briefly up to +90 °C Art. no.Weight (kg)VolumeStacking LoadHolding CapacityDynamic LoadColourRunners83421800 44 kg 620 l 5,000 kg 900 kg 1,900 kg light grey 3, welded *1:

All technical data include characteristic features, which have been tested under specially defined conditions. Varying data may result from different conditions of usage such as loading method, prevailing temperature and length of storage time. All data and specified information are subject to change without notice. Our service team is pleased to be at your disposal to check the special requirements of your individual application.

*2:

Our service team is pleased to be at your disposal if you require exact information about material compositions.

*3:

Stacking load with a holding capacity of 900 kg at room temperature. Dynamic load on a forklift with an evenly distributed load at a room temperature.

- Technical drawings

-

Loading quantities (Pcs / Approximate amount)

Container Container 20': 0 Pcs.

Container 40': 0 Pcs.

Container 40' High Cube: 0 Pcs.

Container 45': 0 Pcs.

Conventional trailer 45’ high cube container: 104 Pcs.Truck MEGA Trailer: 104 Pcs.

Jumbo: 112-120 -

Labeling options

Customised printing and numbering available on request depending on quantity. Position upon consultation.

-

Technical drawings

Administration: Brocker Straße 1

Logistics, delivery, pick-up: Alte Ziegelei 2

33442 Herzebrock-Clarholz

Germany